A form clamp is an essential component of modern construction and the industrial production of reinforced concrete products. Our accessories are the key to fast and easy assembly and disassembly of formwork and auxiliary structures during any concrete work. Make your concreting process simpler and more efficient!

A form clamp is a specialized device used in construction and industry to secure formwork, molds, and structural elements during concrete pouring or working with other materials. The main purpose of a form clamp is to hold components firmly in place, preventing displacement, deformation, or rupture of the structure under the pressure of concrete or other loads. Such clamps ensure accurate geometry, stability of elements, and high quality of the finished construction.

Find everything you need for your formwork at RMS "GROUP" store in Yerevan with delivery! Purchase reliable and modern construction materials from us at affordable prices. We offer a wide range directly from our warehouses. Whether you need just one piece or a large batch — we are ready to supply any quantity.

In construction, form clamps are used in the installation of monolithic structures, reinforced concrete walls, columns, slabs, and foundations. They allow you to secure formwork elements both vertically and horizontally, providing strength and stability throughout the entire concrete pouring and curing process. Clamps are also used in the production of precast concrete products at factories, where precise fixation of molds is required for mass production of blocks, slabs, columns, and other elements.

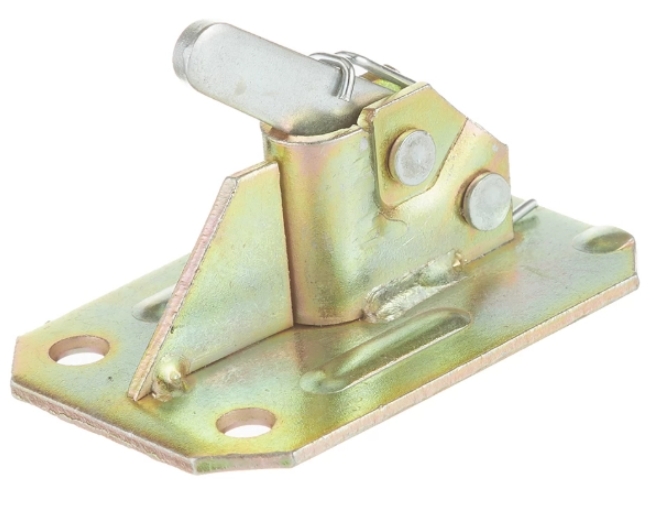

These are metal products made of steel or aluminum alloys, ensuring strength, rigidity, and durability. A clamp may include a body with a fixing screw or a spring mechanism, a lever, and a mounting pad. Some models are equipped with rubber or plastic pads to protect the mold surface and prevent damage.

There are several types of form clamps:

The most popular type is the screw clamp, valued for its versatility, reliability, and adjustable clamping force, making it suitable for most formwork tasks.

The choice of clamp depends on the material, thickness, and weight of the form, as well as working conditions such as humidity, temperature, and concrete pressure.

Using form clamps speeds up the process of formwork assembly and disassembly, enhances precision and pouring quality, reduces the risk of defects, and saves materials. They provide uniform pressure on all mold components, preventing deformation, misalignment, and cracks in the concrete.

Our form clamps feature high performance, durability, and cost efficiency. They make formwork installation simpler and more accurate, ensuring the quality of your concrete work.