Construction laminated plywood of Russian and Belarusian production is available for purchase, weighing 36–43 kg, at the most affordable prices on the market. RMS “GROUP” offers pricing and delivery terms that best meet your technical and economic requirements, fully taking your needs into account.

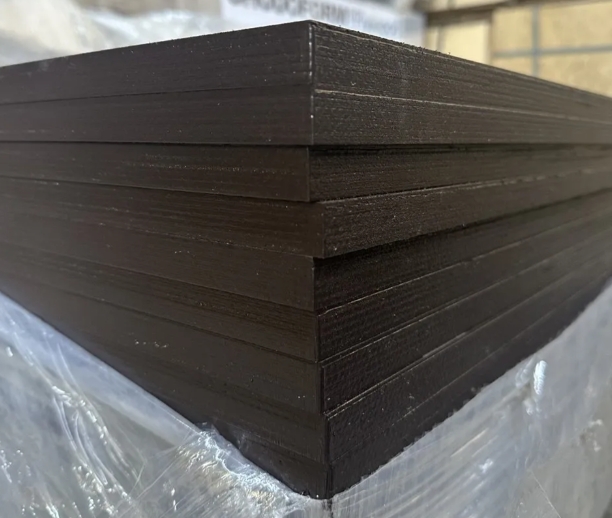

Laminated plywood is a durable multi-layer panel material made from birch or softwood veneer and coated on both sides with a protective phenolic film. Thanks to this coating, the plywood becomes moisture-resistant, wear-resistant, and ideal for intensive operating conditions.

RMS “GROUP” offers laminated formwork plywood for wholesale and retail purchase from leading manufacturers. We guarantee competitive prices and a wide range of sizes and thicknesses. Popular as well as rare options are always available in stock. We provide delivery or self-pickup. Check with our managers about current promotions and discounts.

By wood species:

By surface coating:

By moisture resistance:

At RMS “GROUP”, you can purchase plywood in three quality grades:

The main purpose of laminated plywood is to create strong, smooth, and durable surfaces resistant to moisture, frost, temperature fluctuations, and mechanical loads. The material does not delaminate, maintains its geometry, and withstands repeated wetting and drying cycles. The laminated surface does not absorb dirt, requires no additional finishing, and is easy to maintain. Its high surface hardness makes it suitable for heavy-duty environments — from construction sites to the transport industry.

Common Sizes: 2440x1220 mm, 2500x1250 mm, 3000x1500 mm, 1525x1525 mm. Thickness ranges from 6 to 30 mm, allowing selection for various load requirements.

Application by Size and Thickness:

Using laminated plywood for formwork requires following certain rules to maximize its lifespan and ensure a smooth concrete surface. Before pouring concrete, the surface of the plywood is coated with special release agents (shuttering oils) to prevent the concrete from sticking to the laminated layer. This allows for easy removal of the formwork without damaging the plywood surface.

This is the most critical point. Although the face of the plywood is waterproof, its edges (cut areas) are the weakest points. If you have cut the plywood to fit a size, the cut edges must be sealed with water-resistant paint or silicone. Otherwise, moisture will be absorbed, causing the plywood to swell and delaminate.

Installation and Fastening:

After the concrete has set, the formwork is carefully dismantled. Always clean the surface of concrete residue after each use. After cleaning, it should be dried and stored horizontally, away from direct sunlight.

Depending on the quality (for example, plywood made from birch veneer), laminated plywood can be reused 20 to 50 times with proper care. If you notice small scratches on the lamination, seal them immediately with paint to prevent water from penetrating the wood.

Thanks to direct partnerships with manufacturers, we offer sheet materials at competitive prices. Delivery is available throughout Armenia.

We provide a wide range of building materials for wall and partition concreting, formwork, and building projects. Choosing the right material will ensure excellent results and help your structures last for decades without unnecessary expenses or repairs.